2025 Market Report: Desktop Pick-and-Place Robotics for Microelectronics—Growth, Innovation, and Strategic Insights. Explore Key Trends, Forecasts, and Competitive Dynamics Shaping the Industry.

- Executive Summary and Market Overview

- Key Technology Trends in Desktop Pick-and-Place Robotics

- Competitive Landscape and Leading Players

- Market Size, Growth Forecasts, and CAGR Analysis (2025–2030)

- Regional Market Analysis and Emerging Hotspots

- Challenges, Risks, and Opportunities in Microelectronics Automation

- Future Outlook: Innovation Pathways and Strategic Recommendations

- Sources & References

Executive Summary and Market Overview

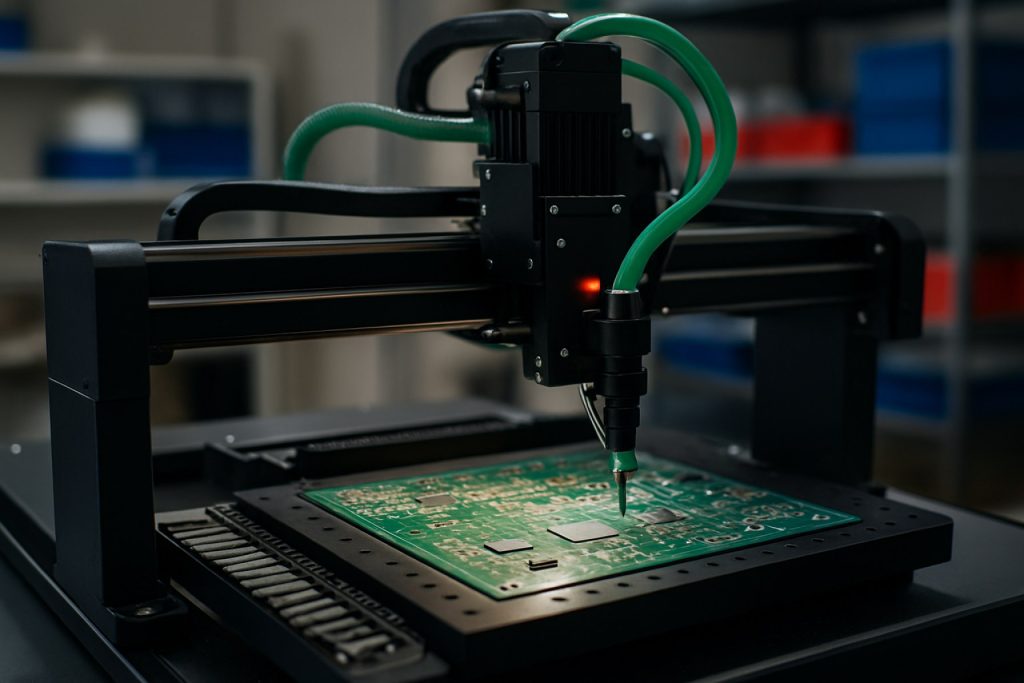

The desktop pick-and-place robotics market for microelectronics is experiencing robust growth in 2025, driven by the increasing demand for miniaturized electronic components, rapid prototyping, and the proliferation of small and medium-sized electronics manufacturers. Desktop pick-and-place robots are compact, automated systems designed to accurately place microelectronic components onto printed circuit boards (PCBs) and other substrates, offering a cost-effective and flexible alternative to large-scale industrial automation.

According to Gartner, the global market for pick-and-place robotics in electronics manufacturing is projected to reach $2.1 billion by 2025, with desktop solutions accounting for a significant share due to their accessibility and adaptability for low-to-medium volume production. The adoption of desktop pick-and-place systems is particularly strong among startups, research labs, and contract manufacturers seeking to accelerate product development cycles and reduce labor costs.

Key market drivers include the ongoing trend toward device miniaturization, the rise of the Internet of Things (IoT), and the need for rapid prototyping in the face of shorter product lifecycles. Desktop pick-and-place robots enable precise handling of components as small as 01005 (0.4mm x 0.2mm), meeting the stringent requirements of modern microelectronics assembly. Additionally, advancements in machine vision, software integration, and user-friendly interfaces have lowered the barrier to entry, making these systems accessible to non-specialist operators.

The competitive landscape features established automation providers such as NeoDen, LCPCB, and Charmhigh, alongside emerging players offering open-source and modular solutions. These companies are innovating with features like automated feeders, real-time quality inspection, and cloud-based monitoring to differentiate their offerings.

Regionally, Asia-Pacific remains the largest market, fueled by the concentration of electronics manufacturing in China, Taiwan, and South Korea. However, North America and Europe are witnessing increased adoption, particularly in the context of reshoring and the growth of local electronics startups. According to IDC, the desktop pick-and-place segment is expected to grow at a CAGR of 12.5% through 2025, outpacing traditional large-scale systems.

In summary, the desktop pick-and-place robotics market for microelectronics in 2025 is characterized by rapid innovation, expanding user bases, and a shift toward flexible, scalable manufacturing solutions that support the evolving needs of the electronics industry.

Key Technology Trends in Desktop Pick-and-Place Robotics

Desktop pick-and-place robotics are rapidly transforming the microelectronics sector, driven by the need for higher precision, miniaturization, and flexible automation in component assembly. In 2025, several key technology trends are shaping the evolution and adoption of these compact robotic systems within microelectronics manufacturing environments.

- Advanced Vision Systems: Integration of high-resolution cameras and AI-powered image processing is enabling desktop pick-and-place robots to achieve sub-micron placement accuracy. These systems can now identify, align, and place increasingly smaller components, such as 01005 (0.4mm x 0.2mm) chips, which are common in advanced microelectronics. Enhanced vision also supports real-time defect detection and adaptive correction, reducing error rates and improving yield (Vision Systems Design).

- AI-Driven Process Optimization: Machine learning algorithms are being embedded into desktop pick-and-place platforms to optimize pick paths, adjust placement force, and predict maintenance needs. This results in faster cycle times and reduced downtime, which is critical for high-mix, low-volume microelectronics production (ABB).

- Miniaturization and Modular Design: The trend toward smaller, modular desktop robots allows manufacturers to deploy automation in limited spaces, such as R&D labs and prototyping facilities. Modular designs enable quick reconfiguration for different board layouts or component types, supporting rapid product development cycles (Universal Robots).

- Integration with Digital Twins and Industry 4.0: Desktop pick-and-place systems are increasingly connected to digital twin platforms, allowing for virtual simulation of assembly processes and predictive analytics. This integration supports real-time monitoring, remote diagnostics, and seamless data exchange across the production line, aligning with broader Industry 4.0 initiatives (Siemens).

- Enhanced User Interfaces and Low-Code Programming: User-friendly interfaces and low-code programming environments are making it easier for non-experts to configure and operate desktop pick-and-place robots. This democratization of automation is accelerating adoption among small and medium-sized enterprises (SMEs) in the microelectronics sector (Rockwell Automation).

These technology trends are collectively driving the adoption of desktop pick-and-place robotics in microelectronics, enabling greater flexibility, precision, and efficiency in the assembly of next-generation electronic devices.

Competitive Landscape and Leading Players

The competitive landscape for desktop pick-and-place robotics in the microelectronics sector is characterized by a mix of established automation giants and specialized niche players, each vying for market share through technological innovation, precision, and adaptability. As of 2025, the market is witnessing intensified competition driven by the miniaturization of electronic components, the proliferation of IoT devices, and the demand for rapid prototyping and small-batch production in research and development environments.

Leading players in this segment include NeoDen Technology, Charmhigh, and Manncorp, all of which have developed compact, user-friendly desktop pick-and-place machines tailored for microelectronics assembly. These companies differentiate themselves through features such as high placement accuracy (often within ±0.02 mm), intuitive software interfaces, and modular designs that allow for quick changeovers between different component types and board sizes.

NeoDen Technology, for example, has expanded its product line with models like the NeoDen K1830, which integrates vision systems and supports a wide range of component sizes, catering to both prototyping and small-scale production needs. Similarly, Charmhigh’s desktop solutions are recognized for their affordability and ease of use, making them popular among startups and academic institutions. Manncorp, with its MC series, emphasizes robust build quality and after-sales support, targeting both entry-level and professional users.

In addition to these key players, the market also features emerging entrants such as LCPCB and AIMotion, which are leveraging advancements in machine vision and AI-driven placement algorithms to enhance speed and accuracy. These innovations are particularly relevant as the industry shifts toward assembling increasingly complex and miniaturized microelectronic devices.

Strategic partnerships and collaborations are also shaping the competitive dynamics. For instance, several leading vendors have formed alliances with PCB manufacturers and software developers to offer integrated solutions that streamline the entire assembly workflow. Furthermore, the growing adoption of Industry 4.0 principles is prompting established players to invest in connectivity and data analytics features, enabling real-time monitoring and predictive maintenance.

Overall, the desktop pick-and-place robotics market for microelectronics in 2025 is marked by rapid technological evolution, a focus on user-centric design, and a competitive push toward higher precision and automation flexibility, as documented in recent industry analyses by MarketsandMarkets and Gartner.

Market Size, Growth Forecasts, and CAGR Analysis (2025–2030)

The global market for desktop pick-and-place robotics in microelectronics is poised for robust expansion between 2025 and 2030, driven by the accelerating miniaturization of electronic components and the demand for higher throughput in assembly lines. According to recent projections by MarketsandMarkets, the overall pick-and-place robotics market is expected to reach USD 6.5 billion by 2030, with the desktop segment in microelectronics representing a significant and fast-growing niche.

In 2025, the desktop pick-and-place robotics segment for microelectronics is estimated to be valued at approximately USD 420 million, accounting for a notable share of the broader electronics assembly automation market. This segment is forecasted to grow at a compound annual growth rate (CAGR) of 12.8% from 2025 to 2030, outpacing the general industrial robotics market, which is projected to grow at a CAGR of around 9% during the same period (IDTechEx).

Several factors are fueling this growth trajectory:

- Proliferation of IoT and Wearable Devices: The surge in demand for compact, high-density electronic assemblies is pushing manufacturers to adopt desktop pick-and-place solutions for prototyping and small-batch production (Gartner).

- SME Adoption: Small and medium-sized enterprises (SMEs) are increasingly investing in desktop automation to enhance flexibility and reduce labor costs, further expanding the addressable market.

- Technological Advancements: Innovations in vision systems, precision placement, and user-friendly interfaces are making desktop pick-and-place robots more accessible and efficient for microelectronics applications (ABB).

Regionally, Asia-Pacific is expected to dominate market share, led by China, Japan, and South Korea, where electronics manufacturing is highly concentrated. North America and Europe are also projected to see steady growth, particularly in R&D and prototyping environments.

In summary, the desktop pick-and-place robotics market for microelectronics is set for double-digit growth through 2030, underpinned by technological innovation, expanding application scope, and the ongoing evolution of the electronics manufacturing landscape.

Regional Market Analysis and Emerging Hotspots

The regional market landscape for desktop pick-and-place robotics in microelectronics is evolving rapidly, driven by the miniaturization of electronic components and the demand for higher production efficiency. In 2025, Asia-Pacific continues to dominate the market, accounting for the largest share due to the concentration of semiconductor manufacturing hubs in countries such as China, Taiwan, South Korea, and Japan. These nations benefit from robust investments in automation and a well-established electronics supply chain. According to SEMI, the Asia-Pacific region is projected to maintain over 60% of global semiconductor fabrication capacity, directly fueling demand for advanced desktop pick-and-place solutions.

North America remains a significant market, propelled by the presence of leading microelectronics innovators and a strong focus on R&D. The United States, in particular, is witnessing increased adoption of desktop pick-and-place robotics among small and mid-sized enterprises (SMEs) and prototyping labs, as these systems offer flexibility and cost-effectiveness for low- to medium-volume production. The Semiconductor Industry Association (SIA) reports that U.S. semiconductor manufacturing investments are expected to grow by over 15% in 2025, supporting further uptake of automation technologies.

Europe is emerging as a hotspot, especially in Germany, France, and the Netherlands, where government-backed initiatives to strengthen domestic semiconductor capabilities are underway. The European Union’s European Chips Act is catalyzing investments in microelectronics manufacturing, with a focus on advanced packaging and assembly processes that benefit from desktop pick-and-place robotics. The region’s emphasis on high-mix, low-volume production for automotive and industrial electronics is also driving demand for flexible, desktop-scale automation.

Emerging markets in Southeast Asia, such as Vietnam, Malaysia, and Thailand, are gaining traction as alternative manufacturing bases. These countries are attracting foreign direct investment (FDI) from global electronics firms seeking to diversify supply chains. According to McKinsey & Company, Southeast Asia’s electronics exports are expected to grow at a CAGR of 8% through 2025, creating new opportunities for desktop pick-and-place robotics vendors.

- Asia-Pacific: Largest market, driven by semiconductor manufacturing hubs.

- North America: Growth in SMEs and prototyping, strong R&D focus.

- Europe: Hotspot for advanced packaging, government-backed investments.

- Southeast Asia: Emerging as a manufacturing alternative, rapid export growth.

Challenges, Risks, and Opportunities in Microelectronics Automation

The landscape of desktop pick-and-place robotics for microelectronics in 2025 is shaped by a dynamic interplay of challenges, risks, and opportunities. As the demand for rapid prototyping, small-batch manufacturing, and agile electronics assembly grows, desktop pick-and-place systems are increasingly adopted by startups, research labs, and small-to-medium enterprises (SMEs). However, this segment faces several hurdles that must be addressed to unlock its full potential.

- Challenges: Precision and repeatability remain critical challenges for desktop-scale systems. Unlike industrial-grade machines, desktop robots often struggle with micron-level accuracy, especially when handling miniaturized components such as 0201 or smaller packages. Additionally, integration with diverse software ecosystems and compatibility with a wide range of component feeders and PCB formats can be problematic. The lack of standardized interfaces and limited support for advanced vision systems further complicate seamless operation and workflow automation (Assembly Magazine).

- Risks: The rapid pace of miniaturization in microelectronics poses a risk of obsolescence for current desktop pick-and-place models. As component sizes shrink and board densities increase, machines that cannot be easily upgraded may quickly become outdated. There is also a cybersecurity risk as more systems become networked for remote monitoring and control, exposing them to potential cyber threats. Furthermore, the influx of low-cost, unproven machines from new entrants—especially from regions with less stringent quality controls—can lead to reliability issues and erode user trust (Institute for Manufacturing, University of Cambridge).

- Opportunities: Despite these challenges, the market for desktop pick-and-place robotics is poised for significant growth. The ongoing trend toward distributed manufacturing and the rise of hardware startups are driving demand for affordable, flexible assembly solutions. Advances in machine vision, AI-driven placement algorithms, and modular hardware design are enabling higher accuracy and easier customization. Strategic partnerships between robotics manufacturers and PCB design software providers are also creating more integrated, user-friendly workflows. According to IDTechEx, the global market for electronics assembly robotics—including desktop systems—is expected to see robust growth through 2025, fueled by innovation and the democratization of electronics manufacturing.

Future Outlook: Innovation Pathways and Strategic Recommendations

The future outlook for desktop pick-and-place robotics in microelectronics is shaped by rapid innovation, evolving end-user requirements, and intensifying competition. As the microelectronics sector continues to miniaturize components and increase assembly complexity, desktop pick-and-place systems are expected to undergo significant technological advancements to meet precision, speed, and flexibility demands.

Key innovation pathways include the integration of advanced machine vision and artificial intelligence (AI) for real-time defect detection, adaptive alignment, and self-optimization. These technologies are anticipated to reduce setup times and improve placement accuracy, directly addressing the needs of prototyping labs and small-batch manufacturers. For instance, AI-driven systems can dynamically adjust to component variations, minimizing human intervention and error rates. Companies such as NeoDen and LCPCB are already incorporating smart vision systems and user-friendly interfaces, setting a precedent for broader industry adoption.

Another innovation trajectory is the development of modular and scalable platforms. As product life cycles shorten and customization becomes more prevalent, manufacturers require flexible solutions that can be easily reconfigured for new projects. Desktop pick-and-place vendors are responding by offering modular feeders, interchangeable nozzles, and software-driven process customization, enabling rapid adaptation to changing assembly requirements.

From a strategic perspective, market participants should prioritize the following recommendations:

- Invest in R&D for AI and Vision Integration: Companies should allocate resources to enhance machine learning algorithms and vision systems, as these are critical differentiators in achieving higher throughput and lower defect rates.

- Expand Ecosystem Partnerships: Collaborating with PCB design software providers and component suppliers can streamline workflows and create value-added solutions for end-users.

- Focus on User Experience: Simplifying machine setup, maintenance, and programming will be essential to attract small and medium-sized enterprises (SMEs) and educational institutions, which represent a growing segment of the market.

- Emphasize Sustainability: Developing energy-efficient machines and supporting lead-free and recyclable materials will align with global environmental regulations and customer expectations.

Looking ahead to 2025 and beyond, the desktop pick-and-place robotics market for microelectronics is poised for robust growth, driven by ongoing innovation and strategic alignment with emerging industry trends. According to MarketsandMarkets, the global pick-and-place robotics market is projected to expand at a CAGR exceeding 13% through 2027, with desktop solutions capturing a significant share due to their accessibility and versatility.

Sources & References

- NeoDen

- Charmhigh

- IDC

- Vision Systems Design

- Universal Robots

- Siemens

- Rockwell Automation

- MarketsandMarkets

- IDTechEx

- European Chips Act

- McKinsey & Company

- Assembly Magazine

- Institute for Manufacturing, University of Cambridge

- NeoDen