Table of Contents

- Executive Summary: Key Findings & Outlook to 2029

- Industry Overview: Fluorescent Label Reagents Defined and Key Applications

- 2025 Market Size, Segmentation, and Top Manufacturers

- Emerging Technologies: From Advanced Dyes to Quantum Dots

- Regulatory Landscape and Quality Standards (Citing ThermoFisher.com, SigmaAldrich.com)

- Supply Chain Innovations and Sustainability Initiatives

- Competitive Analysis: Leading Players and Strategic Alliances

- Regional Perspectives: North America, Europe, Asia-Pacific, and Rest of World

- Market Forecasts 2025–2029: Growth Drivers & Demand Trends

- Future Outlook: Next-Generation Reagents, Automation, and Industry 4.0 Integration

- Sources & References

Executive Summary: Key Findings & Outlook to 2029

The fluorescent label reagent manufacturing sector continues to experience robust growth in 2025, driven by surging demand from life sciences, diagnostics, and pharmaceutical research. Recent years have seen significant advancements in reagent chemistries, improved photostability, and enhanced specificity, which have broadened application scopes for fluorescent labeling in proteomics, genomics, and cell analysis. Major manufacturers are expanding their product lines to include novel fluorophores with improved quantum yields and longer lifetimes, directly addressing emerging needs in high-throughput sequencing, single-cell analysis, and super-resolution microscopy.

Key industry players, such as Thermo Fisher Scientific, Merck KGaA (operating as MilliporeSigma in the U.S. and Canada), and LGC, Biosearch Technologies, have invested in scaling up production facilities and automating quality control processes. In 2024–2025, Thermo Fisher Scientific announced expansions of its fluorescent dye offerings and enhancements in conjugation technologies, supporting higher batch-to-batch consistency and regulatory compliance for clinical and research-grade reagents. Similarly, Merck KGaA has introduced advanced fluorescent labeling kits optimized for multiplexed detection and live-cell imaging, targeting both academic and biopharmaceutical end-users.

Supply chain resilience is a key focus, with leading firms establishing regional distribution centers and forming strategic partnerships with raw material suppliers to mitigate disruptions. Sustainability initiatives are also shaping manufacturing practices, as companies invest in greener synthesis routes and recyclable packaging. Bio-Rad Laboratories has reported progress in reducing hazardous byproducts and energy consumption in its reagent manufacturing operations, aligning with global sustainability goals.

Looking ahead to 2029, industry outlook remains positive, buoyed by the proliferation of precision medicine, growth in molecular diagnostics, and continued innovation in fluorescence-based detection technologies. The integration of artificial intelligence and automation is expected to further streamline manufacturing, enabling rapid adaptation to evolving customer requirements. With regulatory frameworks evolving to ensure product safety and performance, established manufacturers are well-positioned to capitalize on the expanding needs of both research and clinical laboratories.

- Strong demand from life sciences and diagnostics drives market expansion through 2029.

- Leading manufacturers invest in product innovation, automated production, and regulatory compliance.

- Supply chain resilience and sustainability are top operational priorities.

- Emerging applications in genomics and cell-based assays provide new growth avenues.

Industry Overview: Fluorescent Label Reagents Defined and Key Applications

Fluorescent label reagents are specialized chemical compounds designed to emit light upon excitation, enabling the visualization and quantification of biological molecules in a wide range of analytical and diagnostic applications. The manufacturing of these reagents is a sophisticated process, involving organic synthesis, purification, conjugation to biomolecules, and stringent quality control to ensure stability, brightness, and specificity. In 2025, the industry is characterized by both the expansion of established product lines and the introduction of novel fluorophores with improved properties, such as enhanced photostability, multiplexing capability, and reduced background fluorescence.

Key applications for fluorescent label reagents continue to drive manufacturing innovation. These applications include molecular diagnostics (such as real-time PCR and digital PCR), flow cytometry, immunofluorescence microscopy, high-throughput screening, and next-generation sequencing sample preparation. The demand for reagents compatible with automated and high-content screening platforms is rising, necessitating precise formulation and rigorous batch-to-batch consistency during manufacturing.

Major industry players such as Thermo Fisher Scientific, MilliporeSigma (the life science business of Merck KGaA), and Bio-Rad Laboratories have continued to invest in expanding their fluorescent labeling portfolios. For example, Thermo Fisher Scientific has introduced new Alexa Fluor dyes with increased resistance to photobleaching, addressing the needs of researchers performing long-term imaging or multiplexed detection (Thermo Fisher Scientific). Similarly, MilliporeSigma has developed a range of water-soluble fluorescent labels for use in live-cell imaging and flow cytometry applications, focusing on improving signal-to-noise ratios and ease of conjugation to antibodies (MilliporeSigma).

To ensure product consistency and regulatory compliance, manufacturers are implementing advanced analytical characterization techniques and adopting ISO-certified quality management systems. Furthermore, sustainability and green chemistry practices are emerging as priorities, with companies seeking to optimize reagent synthesis to minimize hazardous waste and energy consumption. These trends are likely to influence production methods and supply chain management throughout the next several years.

Looking ahead, the ongoing integration of artificial intelligence (AI) and automation in manufacturing facilities is expected to streamline process optimization and accelerate the introduction of next-generation fluorescent reagents. As the landscape of molecular diagnostics and cell-based assays continues to evolve, manufacturers are poised to address increasing demand from clinical, pharmaceutical, and academic sectors, ensuring a robust and innovative supply of fluorescent label reagents worldwide.

2025 Market Size, Segmentation, and Top Manufacturers

The global market for fluorescent label reagent manufacturing is poised for robust growth in 2025, driven by expanding applications in genomics, proteomics, diagnostics, and pharmaceutical research. Segmentations within this sector are typically based on the type of reagent (such as fluorescent dyes, probes, and conjugates), end-use industry (biotechnology companies, clinical laboratories, academic research), and application (immunoassays, nucleic acid labeling, cell imaging, and flow cytometry).

In 2025, the demand for high-specificity and multiplexing-capable fluorescent labels is expected to intensify as next-generation sequencing (NGS) and advanced flow cytometry platforms become more prevalent. For example, Thermo Fisher Scientific continues to expand its Invitrogen™ product line with advanced Alexa Fluor™ dyes and Qubit™ reagents, supporting applications in both research and clinical diagnostics. Similarly, MilliporeSigma (the life science business of Merck KGaA) offers a wide range of Atto and DyLight fluorescent dyes, which are widely used for protein and nucleic acid labeling.

Regional segmentation reveals that North America and Europe remain dominant markets due to their strong biotechnology and pharmaceutical industries, while Asia-Pacific—particularly China and India—is experiencing rapid growth in reagent manufacturing capacity and domestic demand. Companies like Abcam plc are strengthening their global supply chains to better serve expanding research efforts in these regions, offering extensive portfolios of fluorescent antibodies and labeling kits.

Top manufacturers in 2025 include:

- Thermo Fisher Scientific – A global leader in life science reagents, with significant investments in fluorescent labeling technologies.

- MilliporeSigma (Merck KGaA) – Offers comprehensive labeling reagent solutions for proteomics and genomics.

- Bio-Rad Laboratories, Inc. – Supplies a broad range of fluorescent dye conjugates for flow cytometry and imaging.

- Abcam plc – Focuses on high-quality fluorescent antibodies and multiplexing kits, with expanding global distribution.

- Promega Corporation – Provides novel fluorescent reagents for genetic analysis and cell biology research.

Looking ahead, the fluorescent label reagent market is expected to benefit from increased investment in personalized medicine, molecular diagnostics, and automation in research workflows. Manufacturers are focusing on sustainable production processes and expanding their product lines to meet evolving needs for sensitivity, specificity, and multiplexing in both research and clinical applications.

Emerging Technologies: From Advanced Dyes to Quantum Dots

The fluorescent label reagent manufacturing sector is poised for significant transformation in 2025 and the years immediately ahead, driven by rapid advancements in dye chemistry, quantum dot engineering, and automated synthesis platforms. As research and diagnostics demand more sensitive and multiplexed detection capabilities, manufacturers are responding with innovative reagents that offer improved brightness, stability, and spectral versatility.

Major industry players are introducing next-generation fluorescent dyes with enhanced photostability and reduced background interference. For example, Thermo Fisher Scientific continues to expand its Alexa Fluor and DyLight dye portfolios, emphasizing reagents suitable for super-resolution microscopy and flow cytometry. These new fluorophores are tailored for high-performance applications, offering sharper emission spectra and compatibility with cutting-edge imaging instrumentation.

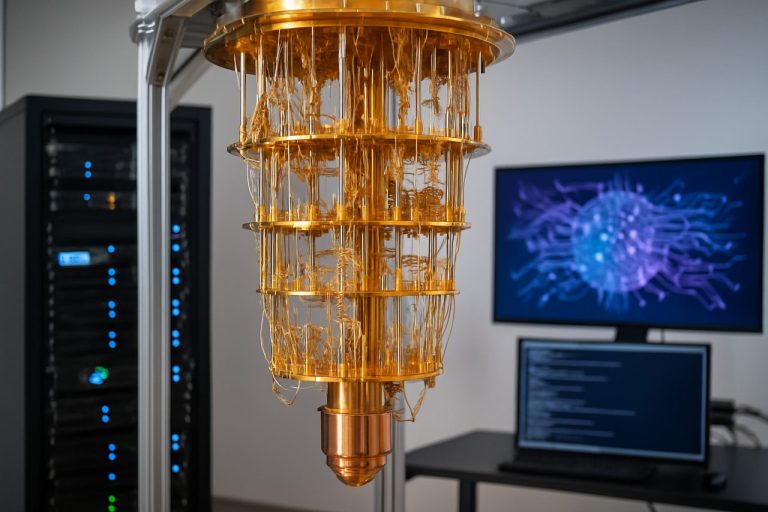

The integration of quantum dot technologies marks another significant trend. Quantum dots, semiconductor nanocrystals with tunable emission properties, are being adopted for their superior brightness and resistance to photobleaching. Manufacturers such as Invitrogen (a brand of Thermo Fisher Scientific) and Merck KGaA are scaling up production and commercial availability of quantum dot reagents, targeting applications in multiplexed immunoassays and single-molecule tracking. These companies are also investing in surface chemistry innovations to improve the aqueous solubility and biocompatibility of their quantum dot products.

Process automation and digitalization are having a pronounced impact on manufacturing workflows. Companies like Luminex Corporation are deploying automated, high-throughput synthesis and purification systems to ensure reproducibility and scalability, critical as demand from genomics, proteomics, and clinical diagnostics continues to rise. Such systems help minimize batch-to-batch variability and accelerate the introduction of bespoke fluorescent label reagents tailored for specific research or diagnostic needs.

Looking ahead, sustainability considerations are influencing raw material sourcing and waste reduction strategies. Organizations such as Sigma-Aldrich (now part of Merck) are developing greener synthetic protocols and implementing recycling initiatives for solvent and reagent waste. These measures are expected to become standard practice across the industry as regulatory scrutiny intensifies.

In summary, 2025 will see fluorescent label reagent manufacturing shaped by advanced dye and quantum dot technologies, greater automation, and a growing emphasis on environmental responsibility. These shifts are expected to drive further innovation, enabling more sensitive, specific, and sustainable labeling solutions for biomedical research and diagnostics.

Regulatory Landscape and Quality Standards (Citing ThermoFisher.com, SigmaAldrich.com)

The regulatory landscape and quality standards for fluorescent label reagent manufacturing are undergoing significant evolution in 2025, reflecting both technological advances and heightened scrutiny from oversight bodies. Fluorescent labeling reagents are critical components in diagnostics, life sciences, and pharmaceutical research, necessitating stringent controls to ensure product safety, consistency, and performance. Globally, manufacturers must comply with regulations such as ISO 13485 for medical device quality management, as well as region-specific requirements like those from the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

Leading manufacturers, such as Thermo Fisher Scientific and Sigma-Aldrich (now part of Merck KGaA), emphasize comprehensive quality management systems that span raw material sourcing, in-process controls, and final product validation. For instance, Thermo Fisher Scientific maintains rigorous protocols for batch traceability, purity validation, and stability testing to meet both internal standards and external regulatory expectations. Their quality documentation supports regulatory submissions, facilitating customer compliance with Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) frameworks (Thermo Fisher Scientific).

Sigma-Aldrich, similarly, adheres to ISO standards and provides detailed Certificates of Analysis and Material Safety Data Sheets with their fluorescent reagents. Their manufacturing processes are designed to minimize variability and contamination, with regular audits and validation of analytical methods ensuring products meet or exceed regulatory and customer expectations. This is increasingly important as more fluorescent reagents are incorporated into clinical and diagnostic workflows, subjecting them to the higher regulatory bar for in vitro diagnostic (IVD) materials. Sigma-Aldrich also highlights the need for compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and other chemical safety directives for distribution in Europe (Sigma-Aldrich).

Looking forward, the next few years are expected to see increasing harmonization of international standards, driven by both regulatory convergence initiatives and industry demand for global consistency. Enhanced digitalization of quality data, automation of quality control, and broader adoption of risk-based approaches are poised to streamline compliance and support rapid innovation. Manufacturers are also preparing for stricter oversight of supply chains and sustainability practices, reflecting broader regulatory and market pressures. As such, the regulatory landscape for fluorescent label reagent manufacturing in 2025 and beyond will be characterized by both higher standards and more integrated, data-driven quality assurance systems.

Supply Chain Innovations and Sustainability Initiatives

The supply chain for fluorescent label reagent manufacturing is undergoing significant transformation in 2025, driven by both technological innovation and a pressing demand for sustainability. As the global market for molecular diagnostics, cell imaging, and life sciences expands, reagent manufacturers are re-engineering their supply chains to improve reliability, reduce environmental impact, and ensure regulatory compliance.

A key trend is the adoption of digitalization and automation for end-to-end supply chain management. Leading players such as Thermo Fisher Scientific and Sigma-Aldrich (Merck KGaA) have invested in advanced inventory management systems to optimize stock levels of critical raw materials and finished fluorophores, minimizing both waste and the risk of shortages. In 2025, these platforms are increasingly integrated with supplier networks, enabling real-time tracking and predictive analytics for better demand forecasting. This digital transformation is also supporting rapid scale-up in response to surges in demand from biotech and pharmaceutical clients.

On the sustainability front, companies are focusing on greener synthesis pathways and recyclable packaging. LGC Biosearch Technologies has implemented processes that use less hazardous solvents and generate lower volumes of chemical waste during dye synthesis, aligning with global calls for reduced environmental footprints in chemical manufacturing. Similarly, Biotium has introduced dye purification methods that significantly reduce water and energy consumption.

Supplier partnerships are also evolving to include sustainability criteria. For instance, Thermo Fisher Scientific has formalized supplier sustainability assessments, evaluating upstream partners on their waste management, emissions, and use of renewable energy. This echoes industry-wide movements to ensure responsible sourcing of raw materials such as specialty chemicals, rare earths, and plastics used in fluorescent reagent packaging.

Looking ahead, circular economy initiatives are expected to gain further traction. Manufacturers are exploring take-back schemes for reagent containers and the use of recycled materials in packaging. Furthermore, the development of biodegradable fluorescent labels—currently in early stages—may offer a long-term solution to the environmental persistence of synthetic dyes.

Overall, supply chain innovation and sustainability initiatives in fluorescent label reagent manufacturing are being shaped by a synergy of digitalization, green chemistry, and collaborative supplier engagement. With continued progress in these areas, the industry is poised to deliver more resilient, transparent, and eco-friendly supply chains over the next several years.

Competitive Analysis: Leading Players and Strategic Alliances

The global fluorescent label reagent manufacturing sector is highly competitive, characterized by a concentrated cluster of established multinational corporations, niche innovators, and strategic partnerships aimed at advancing product offerings and market reach. In 2025, major players continue to leverage their extensive R&D resources and global distribution networks to maintain market leadership, while forming alliances with biotechnology firms and academic institutions to stay at the forefront of emerging applications.

Key competitors include Thermo Fisher Scientific, Merck KGaA (operating as MilliporeSigma in the US and Canada), Agilent Technologies, Bio-Rad Laboratories, and PerkinElmer (now part of Revvity, Inc.). These companies collectively account for a significant share of the global market, owing to broad portfolios that span both classic fluorophores and novel, application-specific dyes. For instance, Thermo Fisher Scientific continues to introduce new Alexa Fluor™ and Invitrogen™ reagents tailored to advanced multiplexing and super-resolution microscopy applications, while Merck KGaA’s recent collaborations with emerging biotech firms are facilitating accelerated reagent development for next-generation sequencing and cell analysis workflows.

Strategic alliances are particularly prominent in 2025, as manufacturers seek to address rapidly evolving user needs in molecular diagnostics, single-cell analysis, and high-throughput screening. The partnership between Bio-Rad Laboratories and Illumina typifies this trend, with joint development efforts focused on integrated solutions for genomics and proteomics. Similarly, Agilent Technologies’ collaborations with academic research centers are enabling the co-development of proprietary fluorescent probes for cancer biomarker detection, further strengthening its competitive position.

- Thermo Fisher Scientific maintains its edge through vertical integration and ongoing investment in reagent innovation, as well as targeted acquisitions that broaden its technology base (Thermo Fisher Scientific).

- Merck KGaA continues to invest in partnerships and in-house development, expanding its range of fluorescent dyes for clinical, industrial, and research markets (Merck KGaA).

- Bio-Rad Laboratories leverages alliances and a robust distribution network to maintain global relevance, particularly in flow cytometry and PCR applications (Bio-Rad Laboratories).

Looking ahead, the competitive landscape is expected to remain dynamic, with increasing emphasis on green chemistry, reagent stability, and integration with digital platforms for data analysis. As market leaders and innovative entrants alike pursue strategic collaborations, the sector is poised for continued expansion and technological advancement beyond 2025.

Regional Perspectives: North America, Europe, Asia-Pacific, and Rest of World

The global landscape for fluorescent label reagent manufacturing is marked by distinct regional trends and strategic developments as of 2025, reflecting both the maturity of established markets and the rapid evolution of emerging economies. North America retains a leading position, driven by robust investment in life sciences, biotechnology, and pharmaceutical research. Key manufacturers such as Thermo Fisher Scientific and PerkinElmer continue to expand their reagent portfolios, leveraging advanced technologies for multiplexed detection and high-throughput applications. Recent facility expansions and R&D collaborations underscore the region’s emphasis on innovation and supply chain resilience.

In Europe, the focus is on sustainable manufacturing processes and compliance with evolving regulatory standards. Major players like Merck KGaA (operating as MilliporeSigma in North America) are investing in greener chemistries for fluorescent labels and increasing their automation capabilities to enhance production efficiency. The European sector benefits from the region’s strong academic-industry partnerships, which facilitate the translation of research breakthroughs into scalable manufacturing processes.

The Asia-Pacific region is experiencing the fastest growth, propelled by expanding biotechnology hubs in China, India, Japan, and South Korea. Companies such as ABclonal and GeneTex are scaling up domestic production capacities and capturing a larger share of the global reagent market. Government initiatives to bolster local life science infrastructure and reduce dependency on imports are further accelerating innovation and competition. Notably, increased investment in clinical diagnostics and biopharmaceutical research is driving demand for high-quality, cost-effective fluorescent labeling solutions.

In the Rest of World category—including Latin America, the Middle East, and Africa—market penetration remains comparatively limited but is gradually increasing. Local distributors and regional players are forming partnerships with global manufacturers to improve access to advanced reagents and technical support. For example, Bio-Rad Laboratories maintains a network of distributors across these regions to support research and clinical laboratories.

Looking forward, the next few years are expected to bring further regional diversification of fluorescent label reagent manufacturing. North America and Europe will likely consolidate their leadership through ongoing investments in automation, digitalization, and sustainability. Meanwhile, Asia-Pacific’s rapid capability expansion is poised to challenge established players, potentially reshaping global supply chains and fostering new innovations tailored to local research needs.

Market Forecasts 2025–2029: Growth Drivers & Demand Trends

The fluorescent label reagent manufacturing sector is set for robust growth from 2025 through 2029, driven by advances in life sciences, diagnostics, and personalized medicine. Increasing application of fluorescent labeling in genomics, proteomics, cell biology, and clinical diagnostics is fostering demand for innovative, high-sensitivity reagents.

Key industry players such as Thermo Fisher Scientific, Merck KGaA (operating as MilliporeSigma in the U.S. and Canada), and Bio-Rad Laboratories have announced ongoing investments in reagent manufacturing capacity, automation, and global supply chain enhancements to keep pace with scientific and clinical demand. For instance, Thermo Fisher Scientific continues to expand its reagent portfolio, focusing on multiplexed fluorescent dyes and antibody conjugates for immunoassays and flow cytometry.

- Precision Medicine & Diagnostics: With the increasing adoption of molecular diagnostics and next-generation sequencing (NGS), the need for highly specific and stable fluorescent label reagents is rising. Merck KGaA highlights the critical role of advanced labeling reagents in enabling sensitive detection in clinical assays and companion diagnostics.

- Research and Academic Demand: Life sciences research, especially in single-cell analysis, CRISPR, and spatial biology, is a major driver. Companies such as Bio-Rad Laboratories are expanding their range of labeled antibodies and dyes to support academic and core facility research.

- Automation & High-Throughput Needs: Demand for reagents compatible with automated platforms is accelerating. Promega Corporation is investing in scalable manufacturing and QC systems to ensure the reproducibility and consistency required for high-throughput screening and clinical applications.

Looking ahead to 2029, supply chain resilience and sustainability will remain priorities for manufacturers. Major players are increasingly adopting green chemistry principles and recyclable packaging, as highlighted by Merck KGaA. Regional manufacturing hubs in North America, Europe, and Asia-Pacific are expected to see capacity expansions to reduce lead times and meet growing local demand.

Overall, the fluorescent label reagent manufacturing market is poised for sustained growth through 2029, underpinned by ongoing innovation, expanding application fields, and strategic investments by leading life science companies.

Future Outlook: Next-Generation Reagents, Automation, and Industry 4.0 Integration

The future of fluorescent label reagent manufacturing is being shaped by rapid advancements in chemistry, automation, and digitalization, laying the groundwork for transformative changes through the rest of this decade. One of the most significant trends is the shift toward next-generation fluorescent dyes and probes, which promise enhanced photostability, reduced background noise, and multiplexing capabilities. Leading manufacturers such as Thermo Fisher Scientific and Merck KGaA (MilliporeSigma) are investing in novel chemistries, such as near-infrared (NIR) and far-red dyes, to support increasingly complex applications in genomics, proteomics, and cell analysis.

Automation is rapidly permeating the manufacturing process, with modular, scalable systems designed to streamline reagent synthesis, purification, and formulation. In 2025, companies like Bio-Rad Laboratories and PerkinElmer are piloting automated production lines for fluorescent reagents, leveraging robotics and real-time quality control analytics to improve batch consistency and throughput. These efforts are complemented by the deployment of advanced informatics platforms to manage supply chain complexity and regulatory compliance.

Industry 4.0 integration is another key driver, bringing together the Internet of Things (IoT), artificial intelligence (AI), and advanced data analytics. For instance, Agilent Technologies is employing connected sensors and cloud-based monitoring systems across its reagent production facilities, enabling predictive maintenance, process optimization, and rapid troubleshooting. This digital transformation not only reduces downtime but also supports more agile responses to shifting market demand and regulatory changes.

Looking ahead to the next few years, the convergence of next-generation reagents and Industry 4.0 principles is expected to dramatically reduce manufacturing cycle times and support the customization of fluorescent probes for emerging applications such as single-cell sequencing, spatial biology, and advanced imaging techniques. Sustainability is also rising in importance, with companies like LGC, Biosearch Technologies investing in greener synthetic pathways and recyclable packaging to address environmental concerns.

Collectively, these innovations are poised to make fluorescent label reagent manufacturing more efficient, responsive, and capable of meeting the evolving needs of life sciences research, clinical diagnostics, and biopharmaceutical development through 2025 and beyond.