Table of Contents

- Executive Summary: 2025 Industry Snapshot & Strategic Insights

- Key Drivers Accelerating Nanodiamond Surface Functionalization Adoption

- Emerging Functionalization Techniques: Innovations & IP Landscape

- Market Size & Growth Forecasts (2025–2030): Demand, Revenue, and Regional Trends

- Application Deep Dive: Biomedical, Electronics, Energy, and Beyond

- Major Players & Partnerships: Companies Shaping the Future

- Supply Chain Analysis: From Nanodiamond Production to End-Use Integration

- Regulatory Landscape & Industry Standards (ISO, IEEE)

- Investment Trends, M&A Activity, and Startup Ecosystem

- Future Outlook: Disruptive Technologies, Opportunities, and Competitive Strategies

- Sources & References

Executive Summary: 2025 Industry Snapshot & Strategic Insights

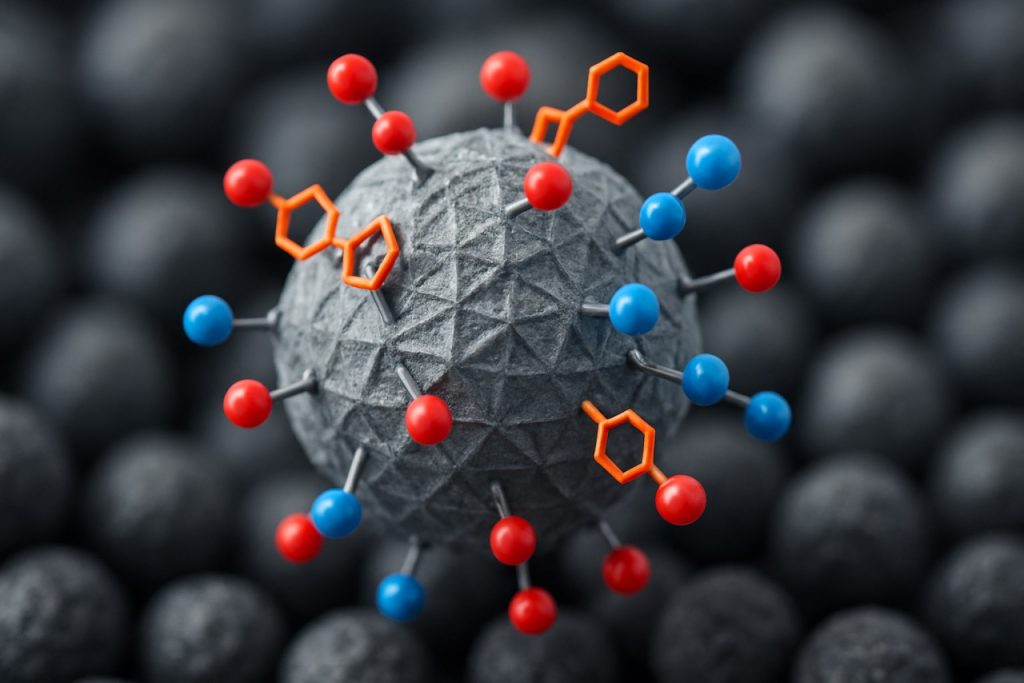

The nanodiamond surface functionalization sector in 2025 is positioned at a transformative juncture, driven by advancements in surface chemistry, expanding commercial applications, and robust industrial investment. Nanodiamonds—nanoscale diamond particles—offer unique properties such as high biocompatibility, tunable surface chemistry, and thermal conductivity, making them increasingly valuable for a range of industries including electronics, biomedical, and advanced manufacturing.

In 2024 and early 2025, several key manufacturers have announced enhanced capabilities to functionalize nanodiamond surfaces with carboxyl, amine, and other functional groups, enabling precise integration into composites, drug delivery systems, and lubricants. For instance, Adamant Namiki Precision Jewel Co., Ltd. has expanded its portfolio of surface-modified nanodiamonds, targeting high-value electronics and quantum sensing markets. Meanwhile, ITOCHU Corporation and its subsidiary ITO Diamond are leveraging proprietary surface treatment processes to improve nanodiamond dispersion in polymers, enhancing mechanical and thermal performance.

Commercial data from 2025 show a marked increase in industrial partnerships, especially in the biomedical space, where surface-functionalized nanodiamonds are being incorporated into targeted drug delivery and imaging agents. Carbon Waters has reported successful scale-up of nanodiamond surface modification processes for integration into anti-corrosion coatings and lubricants, offering improved wear resistance and extended product life. In parallel, SinoCrown Diamond Co., Ltd. has focused on developing functionalized nanodiamonds for next-generation polishing slurries, reporting increased demand from the semiconductor and optics sectors.

Looking ahead to 2026 and beyond, industry stakeholders anticipate further market expansion as regulatory frameworks clarify standards for nanomaterials and as functionalization techniques become more cost-effective and environmentally sustainable. Companies such as Adamant Namiki Precision Jewel Co., Ltd. and Carbon Waters are expected to scale production and deepen collaborations with end-users in electronics, medical devices, and energy storage. As nanodiamond surface functionalization matures, it is set to become a cornerstone technology underpinning high-performance, next-generation materials across multiple high-tech sectors.

Key Drivers Accelerating Nanodiamond Surface Functionalization Adoption

The adoption of nanodiamond surface functionalization is accelerating in 2025, driven by advances in material science, expanding application domains, and increased industrial investment. Several interlocking factors are catalyzing this growth, as outlined below.

- Pharmaceutical and Biomedical Demand: The biocompatibility and customizable surface chemistry of nanodiamonds are propelling their use as drug delivery vehicles, imaging agents, and biosensors. Companies such as Adámas Nanotechnologies are expanding their portfolios of functionalized nanodiamonds tailored for bioimaging and diagnostics, responding to pharmaceutical partners seeking enhanced targeted delivery and reduced toxicity.

- Advanced Manufacturing and Electronics: The electronics sector is increasingly leveraging surface-modified nanodiamonds for their superior thermal conductivity, dielectric properties, and wear resistance. ITO Technology has reported advancements in integrating functionalized nanodiamonds within composite materials for thermal management in semiconductor manufacturing, supporting miniaturization and improved device reliability.

- Emergence of Scalable Surface Modification Techniques: Recent progress in scalable, reproducible surface functionalization methods—such as plasma treatments and wet chemical processes—has reduced production costs and variability. Carbon Waters has implemented scalable surface chemistry protocols, enabling the delivery of ton-scale batches of functionalized nanodiamonds for energy and lubricant applications.

- Environmental and Energy Applications: There is a growing focus on nanodiamonds for energy storage and water purification. Element Six, a subsidiary of De Beers Group, has been developing functionalized nanodiamond materials for electrochemical applications, including supercapacitors and advanced electrodes, highlighting the environmental sustainability and performance benefits.

- Collaborative R&D and Standardization: Cross-sector collaboration and the establishment of industry standards are facilitating broader adoption. Organizations such as the Diamond Innovation division are working with academic and industrial partners to standardize nanodiamond surface chemistry, ensuring consistent quality and compatibility across markets.

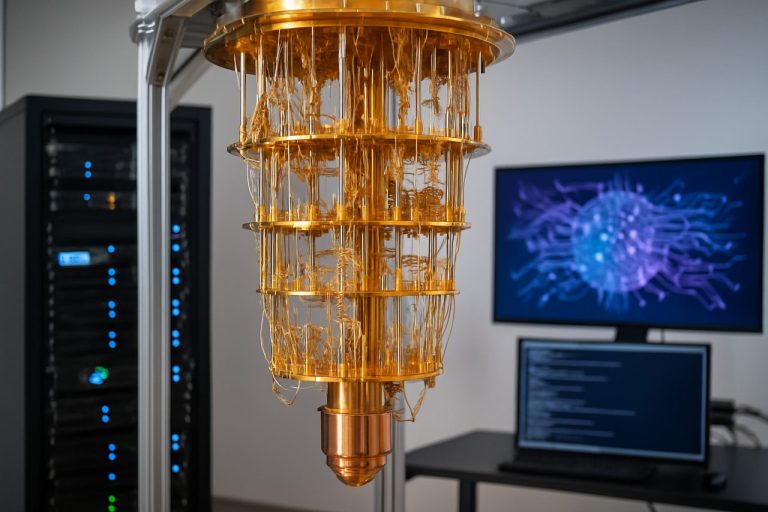

Looking forward, these drivers are expected to intensify, particularly as regulatory clarity improves and the cost of functionalization technologies continues to decrease. The ongoing diversification of application fields—from quantum computing to advanced coatings—ensures sustained momentum for nanodiamond surface functionalization through 2025 and beyond.

Emerging Functionalization Techniques: Innovations & IP Landscape

In 2025, nanodiamond surface functionalization stands as a dynamic area of innovation, propelled by the demand for tailored nanodiamond materials in quantum technology, biomedical, and advanced composite applications. Recent years have witnessed a shift from conventional acid treatments and hydrogenation toward more sophisticated, application-specific surface modification techniques. The industry focus has been on scalable, reproducible, and environmentally friendly functionalization methods.

Key innovators such as Adámas Nanotechnologies and Carbon Waters are driving this evolution by introducing proprietary surface chemistries. Adámas Nanotechnologies, for instance, developed scalable protocols for attaching bioactive molecules and fluorescent tags to nanodiamond surfaces, enabling their widespread use in fluorescence imaging and quantum sensing. Carbon Waters focuses on dispersible nanodiamond suspensions, utilizing advanced plasma and wet chemistry techniques to achieve stable, functionalized colloids for energy storage and lubrication sectors.

A notable trend in 2025 is the rise of ‘click chemistry’ and enzymatic functionalization approaches, offering high selectivity and mild reaction conditions. Companies like Element Six have reported advances in covalent and non-covalent surface modification to engineer specific interactions with polymers or biomolecules, with pilot-scale demonstrations aimed at commercial composite and medical device integration.

The intellectual property (IP) landscape has grown increasingly competitive. Patent filings have surged, particularly in the domains of photonic and quantum applications, where surface functionalization directly impacts device performance and stability. For example, Element Six continues to expand its patent portfolio around nanodiamond coatings and surface-bound color centers for quantum computing and secure communications. Meanwhile, Adámas Nanotechnologies is actively protecting its innovations in bioconjugation and diagnostic reagent development.

Looking ahead, the next few years are expected to bring further convergence between green chemistry and nanodiamond functionalization, as regulatory and customer pressures mount for sustainable nanomaterials. Several industry players are investing in water-based and catalyst-free surface treatment methods to minimize environmental impact while maintaining precision and scalability. Efforts to standardize surface characterization, led by international collaborations involving manufacturers and end-users, aim to accelerate commercial adoption and interoperability. Overall, as functionalization techniques mature, the sector is poised for rapid growth in advanced electronics, therapeutics, and quantum technologies, with robust IP strategies underpinning competitive differentiation.

Market Size & Growth Forecasts (2025–2030): Demand, Revenue, and Regional Trends

The market for nanodiamond surface functionalization is poised for robust growth from 2025 to 2030, driven by intensifying demand across sectors such as biomedicine, electronics, and advanced manufacturing. As global industries pursue heightened performance and miniaturization, nanodiamonds—especially those with precisely engineered surfaces—are increasingly integral in enabling novel solutions for drug delivery, quantum sensing, and high-durability coatings.

Demand for surface-functionalized nanodiamonds is anticipated to climb steadily, with North America, Europe, and East Asia emerging as primary growth regions. The United States remains a leader, propelled by ongoing collaborations between industry and research institutions, and by the scaling up of production capabilities by companies like Adámas Nanotechnologies, which specializes in surface-modified nanodiamonds for bioimaging and diagnostics. In Europe, organizations such as Carbon Waters are advancing the commercial availability of functionalized nanodiamond suspensions tailored for industrial and environmental applications.

Asia-Pacific, particularly China and Japan, is witnessing accelerated adoption of nanodiamond technologies. Companies like ITOCHU Techno-Solutions and Henan Huanghe Whirlwind are enhancing the capacity to offer high-purity, surface-engineered nanodiamonds at scale, meeting growing regional demand in microelectronics and precision manufacturing.

Revenue growth is expected to reflect these trends, as the market transitions from small-batch specialty production to more standardized, scalable offerings. Leading suppliers are investing in advanced surface functionalization techniques—such as carboxylation, amination, and PEGylation—enabling greater customization for end-users in pharmaceuticals and quantum computing. Further, regulatory tailwinds, especially for medical applications in the United States and EU, are expected to ease commercialization pathways for functionalized nanodiamond products.

Looking ahead, the period from 2025 to 2030 will likely see intensified competition and consolidation, as new entrants emerge and established players expand manufacturing footprints. Regional trends indicate that Asia-Pacific may outpace other regions in volume growth, while North America and Europe will maintain leadership in high-value applications. Key industry stakeholders—including Adámas Nanotechnologies, Carbon Waters, ITOCHU Techno-Solutions, and Henan Huanghe Whirlwind—are set to shape the evolving landscape through innovation and strategic partnerships.

Application Deep Dive: Biomedical, Electronics, Energy, and Beyond

Nanodiamond surface functionalization is emerging as a key enabler for advanced applications across biomedical, electronics, and energy sectors, with significant progress anticipated through 2025 and beyond. The unique properties of nanodiamonds—such as high surface area, tunable chemistry, and exceptional biocompatibility—are being harnessed through precise surface modifications to address sector-specific challenges.

In the biomedical field, surface functionalization of nanodiamonds has gained momentum particularly for drug delivery, bioimaging, and biosensing applications. By attaching functional groups (such as carboxyl, hydroxyl, or amine) or biomolecules to the nanodiamond surface, researchers are achieving targeted delivery and enhanced cellular uptake. For example, companies like Adamant Namiki Precision Jewel Co., Ltd. are actively developing functionalized nanodiamonds tailored for use in quantum sensing and bioimaging, exploiting surface chemistry to bind fluorescent markers and targeting ligands for in vivo applications.

In electronics, surface-modified nanodiamonds are being integrated into next-generation quantum devices and sensors. The ability to control surface termination is crucial for stabilizing nitrogen-vacancy (NV) centers, which are pivotal for quantum computing and magnetometry. Element Six, a subsidiary of the De Beers Group, has recently expanded its research and manufacturing capabilities to produce nanodiamonds with engineered surfaces, supporting the scalability of quantum photonics and high-performance electronic components.

For energy storage and conversion, functionalized nanodiamonds are showing promise as additives in battery electrodes and supercapacitors, enhancing conductivity and stability. Companies such as Zhengzhou Sino-Crystal Diamond Co., Ltd. are supplying nanodiamond materials with tailored surfaces for use in next-generation energy devices, focusing on optimizing dispersion and interfacial compatibility with electrode materials.

Looking ahead, the next few years are expected to bring further standardization and commercialization of nanodiamond surface functionalization processes. Industry organizations like the International Diamond Science & Technology Network are fostering collaboration on protocols for surface engineering, which will streamline regulatory approval and accelerate adoption in clinical and industrial settings. As synthesis and modification technologies mature, the versatility of nanodiamonds is set to expand, opening up new applications in catalysis, water purification, and environmental sensing by 2026 and beyond.

Major Players & Partnerships: Companies Shaping the Future

The nanodiamond surface functionalization sector is experiencing significant momentum in 2025, driven by advanced research and strategic collaborations among leading industry players. These efforts focus on optimizing surface chemistry to unlock nanodiamonds’ full potential in applications ranging from quantum sensing to biomedicine and advanced coatings.

One of the most prominent organizations in this field is Adamas Nanotechnologies, which has continued to expand its portfolio of functionalized nanodiamond products. In early 2025, the company introduced new batches of carboxylated and amine-functionalized nanodiamonds, tailored for increased dispersibility in aqueous and organic solvents—key for biological labeling and drug delivery systems. Their active engagement with academic and pharmaceutical partners has accelerated the translation of nanodiamond-based diagnostics toward commercial viability.

Another major force is Element Six (a member of the De Beers Group), which leverages decades of expertise in synthetic diamond production. In 2024–2025, Element Six expanded its proprietary surface modification techniques, collaborating with quantum technology companies to optimize NV-center stability and surface passivation. Their partnerships are shaping the integration of functionalized nanodiamonds in next-generation quantum sensors and computing components.

On the materials innovation front, ITOCHU Corporation continues to invest in large-scale production of high-purity nanodiamonds with customized surface terminations. Their work in 2025 focuses on scalable oxidation and hydrogenation processes, enabling downstream partners in electronics and energy storage to access consistent, application-tailored nanodiamond batches.

In the biomedical sector, Microdiamant (now part of the Hyperion Materials & Technologies group) has deepened collaborations with medical device manufacturers. The company’s recent launch of biofunctionalized nanodiamond dispersions builds on their expertise in precision polishing, targeting applications in implant coatings and therapeutic carriers where biocompatibility and functional surface groups are critical.

Looking ahead, these leaders are increasingly forming cross-sector alliances—combining expertise in diamond synthesis, surface chemistry, and application engineering. The outlook for 2025 and beyond points toward further integration of functionalized nanodiamonds in quantum devices, targeted drug delivery, and high-performance composites. With new entrants focusing on green synthesis and advanced analytics, the competitive landscape is poised for both diversification and rapid innovation.

Supply Chain Analysis: From Nanodiamond Production to End-Use Integration

Nanodiamond surface functionalization stands as a critical step in the nanodiamond value chain, bridging raw material production and application-specific integration. As of 2025, the sector is experiencing rapid evolution, primarily driven by expanding demand in biomedicine, quantum sensing, and advanced composites. Companies are scaling up both the diversity and precision of surface modification techniques to meet stringent performance and regulatory requirements.

Key industry participants, such as Adámas Nanotechnologies and ITOCHU Corporation (through its subsidiary ITO Diamond), have established robust supply chain partnerships to ensure reliable access to detonation and high-pressure high-temperature (HPHT) nanodiamond feedstocks. These firms are investing heavily in proprietary post-synthesis processing, including purification, oxidation, amination, and carboxylation, to tailor nanodiamond surfaces for specific end uses. For example, Adámas Nanotechnologies offers nanodiamonds with custom surface groups designed for bioimaging and drug delivery, while ITO Diamond provides products functionalized for electronic and composite applications.

Recent data from SINTA Corporation highlight increased investment in inline quality control and real-time surface analysis technologies—such as XPS (X-ray photoelectron spectroscopy) and FTIR (Fourier-transform infrared spectroscopy)—to monitor batch-to-batch consistency in surface functionalization. This is critical for downstream partners, particularly in pharmaceutical and quantum device manufacturing, where surface chemistry directly impacts product efficacy and safety.

Looking ahead to the next several years, the outlook suggests further vertical integration as manufacturers seek to minimize supply chain disruptions and secure intellectual property around advanced surface modification methods. Industry leaders anticipate heightened collaboration between nanodiamond suppliers and end-users, especially in regulated sectors like medical devices, where co-development of functionalization protocols is required to achieve both performance and compliance. Additionally, sustainable and scalable surface modification processes—such as plasma-based methods and green chemistry approaches—are under active development with pilot initiatives from firms including NanoInnova Technologies.

In summary, as the nanodiamond market matures through 2025 and beyond, surface functionalization remains a linchpin for supply chain agility and end-use innovation. The sector is characterized by growing technical sophistication, strategic partnerships, and a clear trend toward application-driven customization.

Regulatory Landscape & Industry Standards (ISO, IEEE)

The regulatory landscape and industry standards for nanodiamond surface functionalization are evolving in response to the expanding applications of nanodiamonds across biomedicine, quantum technologies, and advanced manufacturing. As of 2025, regulatory bodies and standards organizations are intensifying efforts to ensure product consistency, safety, and interoperability, with a particular focus on surface-modified nanodiamond materials.

The International Organization for Standardization (ISO) has continued to expand its nanotechnology standards portfolio. ISO/TC 229, the technical committee dedicated to nanotechnologies, has prioritized the development of guidelines for surface characterization and chemical modification of nanomaterials. In 2024, ISO published updates to ISO 10993-22, addressing the biological evaluation of medical devices containing nanomaterials, including nanodiamond coatings and functionalized surfaces. Ongoing work aims to further refine ISO/TR 13014, which provides guidance on physicochemical characterization of engineered nanoscale materials prior to toxicity testing. These standards are directly influencing the required protocols for companies functionalizing nanodiamond surfaces for medical and industrial applications.

In parallel, the Institute of Electrical and Electronics Engineers (IEEE) has advanced the standardization of quantum materials and devices, with relevance to nanodiamonds functionalized for quantum sensing and photonics. The IEEE P7130 working group, focused on quantum technologies terminology, has begun incorporating definitions and best practices related to nanodiamond surface engineering, targeting improved reproducibility and data reporting for quantum-grade nanodiamond products.

From an industry perspective, leading nanodiamond manufacturers such as Adamant Namiki Precision Jewel Co., Ltd. and Smithson Nanodiamond are actively engaging with standards development organizations. These companies are implementing in-house quality management systems aligned with ISO 9001 and participating in interlaboratory trials to benchmark surface functionalization methods. Their efforts reflect a broader industry trend towards harmonization of product specifications, supporting both regulatory compliance and customer confidence.

Looking ahead, the next few years are expected to see increased integration of ISO and IEEE standards into national regulatory frameworks, especially for biomedical and quantum applications. Regulatory agencies in the EU and US have signaled intentions to update technical guidance for nanomaterials, emphasizing traceability, risk assessment, and performance validation of functionalized nanodiamond products. As surface functionalization techniques become more sophisticated, compliance with evolving standards will be critical for market access and cross-border collaboration.

Investment Trends, M&A Activity, and Startup Ecosystem

The nanodiamond surface functionalization sector is experiencing accelerated investment and corporate activity as its applications broaden across quantum technologies, biomedical devices, and advanced materials. In 2025, venture capital and strategic corporate funds are increasingly targeting startups and scale-ups innovating in nanodiamond surface chemistry, driven by the potential to enhance product performance in biocompatibility, drug delivery, and sensing.

A notable investment trend is the influx of funds into companies developing scalable and reproducible surface modification techniques. For example, Adámas Nanotechnologies has attracted new funding rounds with its proprietary nanodiamond functionalization processes tailored for quantum sensing and bioimaging. The company’s focus on uniform surface chemistry to enable reliable conjugation with biomolecules is directly aligned with current market demand for high-purity, application-ready nanodiamonds.

Mergers and acquisitions (M&A) are also reshaping the landscape. In 2024 and early 2025, there has been a particular focus on vertical integration, as larger materials companies seek to gain in-house capabilities in nanodiamond surface modification. Element Six, a leader in synthetic diamond production, has signaled increased interest in partnerships and potential acquisitions to enhance its functional materials division, particularly with an eye on the quantum sensing and medical diagnostics markets. This strategy is indicative of established players recognizing the value of functionalized nanodiamonds for next-generation device platforms.

The startup ecosystem is active, especially in North America and Europe, where university spin-outs and early-stage companies are leveraging advances in surface chemistry to address long-standing commercialization hurdles. Startups such as Carbon Waters are developing innovative surface modification methods to improve nanodiamond dispersibility and compatibility in polymer composites and coatings, attracting both strategic investors and R&D partnerships with established materials firms. Meanwhile, Mikro+Polo continues to expand its product lines with functionalized nanodiamond powders for research and industrial customers.

Looking forward, the sector anticipates continued growth in investment and M&A as the technology matures and end-use markets (e.g., quantum computing, targeted therapeutics) move toward commercialization. Increased standardization—driven by collaborations with organizations such as ISO (International Organization for Standardization)—is expected to further de-risk investment and facilitate scaling. Overall, nanodiamond surface functionalization stands as a vibrant, strategically important frontier, attracting diverse capital and fostering an expanding ecosystem of innovation.

Future Outlook: Disruptive Technologies, Opportunities, and Competitive Strategies

Nanodiamond surface functionalization is poised to be a disruptive force across multiple sectors as 2025 approaches, with significant advancements anticipated in biomedical, quantum, and advanced materials applications. The unique surface chemistry of nanodiamonds, combined with their exceptional biocompatibility, enables the attachment of diverse functional groups, broadening their utility in targeted drug delivery, biosensing, and quantum information systems.

One of the most promising disruptive technologies is the scalable, reproducible functionalization of detonation nanodiamonds for use in medical diagnostics and therapeutics. For example, Adámas Nanotechnologies has demonstrated advanced surface engineering to enhance nanodiamond dispersibility and enable covalent linking with biomolecules, supporting applications from fluorescence labeling to drug delivery. In the coming years, further refinement of surface modification protocols is expected, with a focus on achieving high-yield, site-specific conjugation and minimizing batch-to-batch variability.

Another opportunity lies in quantum technologies. Surface treatment techniques that preserve or improve the spin properties of nitrogen-vacancy (NV) centers in nanodiamonds are critical for quantum sensing and computing. Element Six, a subsidiary of De Beers Group, is actively developing processes for producing high-purity nanodiamonds with engineered surfaces to optimize NV center performance, which could catalyze breakthroughs in nanoscale magnetometry and imaging.

In advanced materials, the functionalization of nanodiamond surfaces is unlocking new frontiers in composite manufacturing, lubrication, and coatings. Itaforte, a supplier specializing in diamond-based materials, is exploring new surface modifications to enhance nanodiamond integration into polymers and metals, targeting improved mechanical, thermal, and tribological properties. The next few years are likely to see intensified competition among suppliers to develop proprietary surface chemistries that deliver superior performance and address customer-specific challenges in sectors such as aerospace and electronics.

From a strategic perspective, partnerships between nanodiamond producers and end-user industries are anticipated to accelerate technology transfer and commercialization. Strategic alliances, such as those between Adámas Nanotechnologies and medical device innovators or between Element Six and quantum computing companies, will likely become more prevalent as companies seek to capture emerging markets. Intellectual property around functionalization chemistries and application-specific nanodiamond formulations will be a key battleground, stimulating investment in R&D and patent portfolios.

Overall, the next several years will be marked by rapid progress in nanodiamond surface functionalization, with disruptive potential for medicine, quantum technology, and materials science. Companies that can deliver scalable, consistent, and application-tailored nanodiamond products will be well positioned to capture significant value in this evolving landscape.